Technologies

Precious hands on experience of Midhani and Nalco helped UADNL in achieving a upper hand on technology and management at the outset itself. The same can be visible as the team of UADNL has decided to set up a world class manufacturing facilities as mentioned below,

- Melting & Alloy making facilities

- Melting furnaces: 3 No’s with 55 Ton capacity each

- Holding Furnaces: 2 No’s with 50 Ton capacity each

- Large-Scale Hot-Rolling Line

- Reheating furnace: 3 No’s with matching capacity

- Hot Rolling mill (4-Hi single stand reversing mill)

- DC Casting Facilities

- Slab Caster: 2 No’s with 50 Ton Capacity each

- Slab & Billet caster: 1No’s with 15 Ton Capacity

- Homogenizing furnaces: 4 No’s with 50 Ton Capacity

- Thermal Treatment Facilities

- Solution heat treatment, quenching, Aging furnaces for plates

- Annealing furnaces for coils

- CASH line – sheets

- Scalping & sawing units

- Stretcher

- Finishing Line

- Packaging & Dispatch sections

- Al-Li Alloy Making Facilities

- Cold Rolling line

- Six – Hi single stand non-reversing mill

Research and Development: Briefly describe plan of action on the R&D activities

- Technology transfer from DRDO & well known international resources.

- Developing the team with international team for continuous strive for development & improvement of process & products performances.

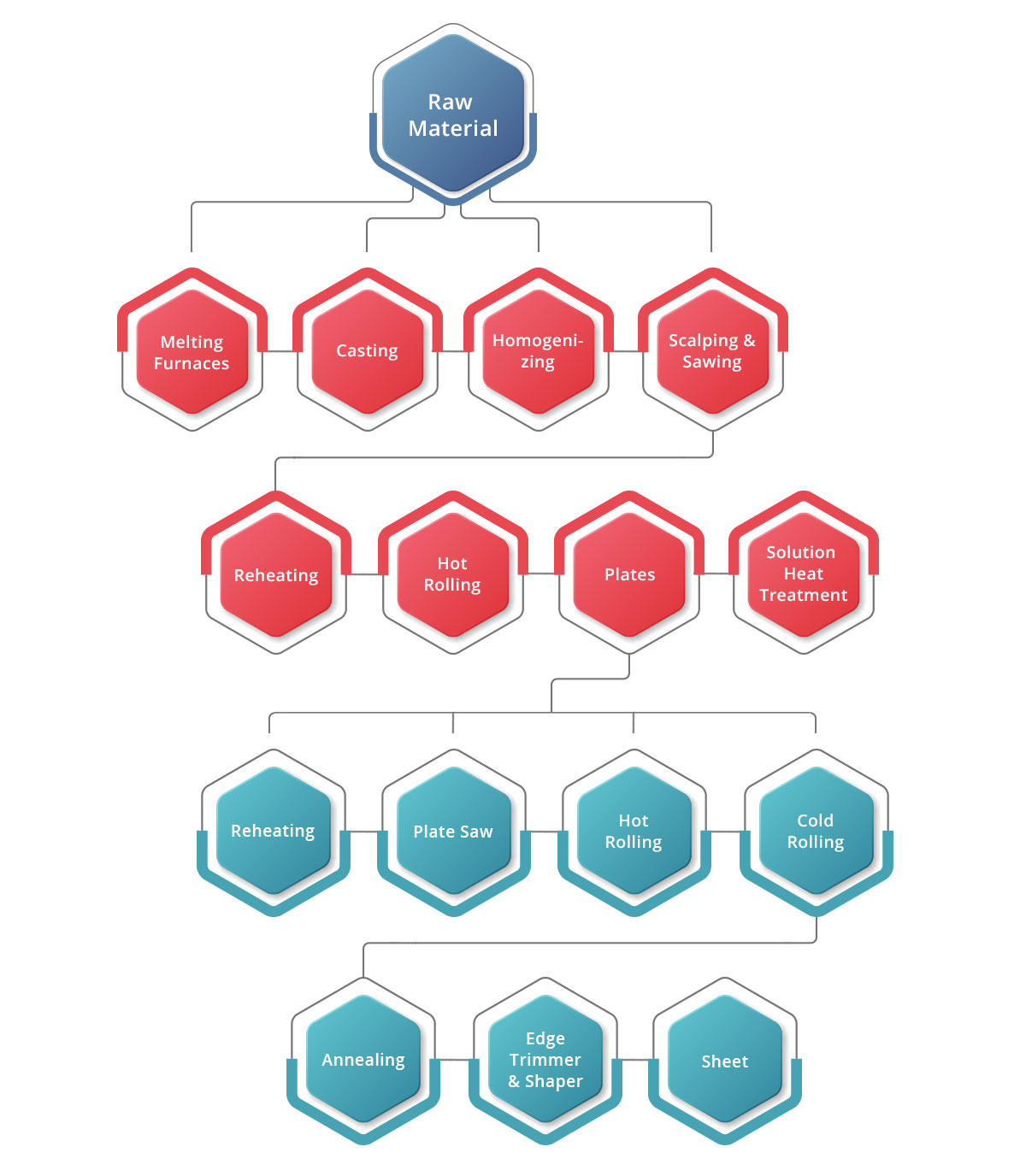

Process Flow